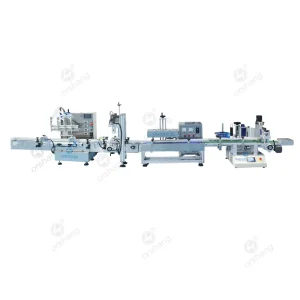

Liquid filling sealing capping and labeling lroduction line

Please come to visit Orshang automation equipment manufacturer, liquid filling and sealing machine production line. This equipment offers the complete package of fully automated liquid filling, sealing, capping, and labelling of nylon or glass and other containers for the food and beverage, pharmaceutical, pet supplies and cosmetics sectors. The line makes work operates smoothly; it eliminates wastage and makes certain that quality products are produced. The following article works to describe its work principle, the most beneficial features and the domains it is suitable for.

Product parameters:

| Filling accuracy: | ±1%mm |

|---|---|

| Filling speed: | 40~50pcs/minutes |

| Labeling accuracy: | ±1mm |

| Applicable length: | 40-400mm |

| Applicable width: | 40-200mm |

| Labeling speed:: | 25 - 35pcs/min |

| Applicable heightr: | 0.2mm-150mm |

| Machine size (L*W*H) : | 5600*3000*2100(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 850KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

The working principle of the production line:

Automatic liquid filling equipment: put the empty bottles in order to be filled on the station, start the machine that starts automatic liquid bottling equipment.

Automatic lifting machine capping machine: the cap will be in the bulk processing, the cap is poured into the capping machine barrel, through the lifting of the cap will be sorted out in a uniform direction to send out.

Liquid filling capping and screwing equipment: move the filled products to the capping station, put the caps in order and start the machine to start capping and sealing.

Aluminium foil sealing solution for liquid products: the aluminium foil sheet on the bottle mouth instantly generates high heat and then fuses on the bottle mouth, so as to achieve the function of sealing and easy to keep for a long time.

Coding machine: print the production date, batch number and expiry date according to the product demand.

Automatic labelling machine: automatically stick the label on the bottle according to the preset parameters.

Advantages of liquid filling, sealing and capping production line:

The operation is very simple:

New comers can be allowed to do it individually without involving serious training. Animated and modifiable operated control touch system, fault occurrence is visible with a Human-Machine Interface operation.

High precision and low waste:

A sophisticated system of filling and sealing contributes to the effective filling of only the right amount of liquid in the bottles, thus increasing on the use of the product.

Versatility in use for a vast number of beverages and a variety of sized bottles:

The line has a capacity to fit different shapes and sizes of bottles for the various products on the market.

Automated filling with an automation operation of a product that is completely automatic:

It has been explicitly designed to be fully automated so that even a single operator can manage the complete liquid filling line.

Long-term cost-effectiveness:

Lower labour cost, less product scrapping and increased productivity lead to long-term saving.

Ideal markets:

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

The filling line can handle a wide range of liquids, from thin beverages to thicker products in pharmaceuticals or cosmetics.

Yes, it can be adjusted according to bottle type and size requirements, suitable for diversified production needs.

The price of the production line varies according to the equipment type, customer needs and configuration, it is recommended to communicate with our manufacturers according to the specific needs and budget, according to your needs to recommend you the perfect automated filling production line solutions.

The production line meets the quality, hygiene and safety standards in the fields of food, cosmetics and pharmaceuticals. It is made of corrosion-resistant stainless steel and meets the requirements of GMP certification.

Reviews

There are no reviews yet.