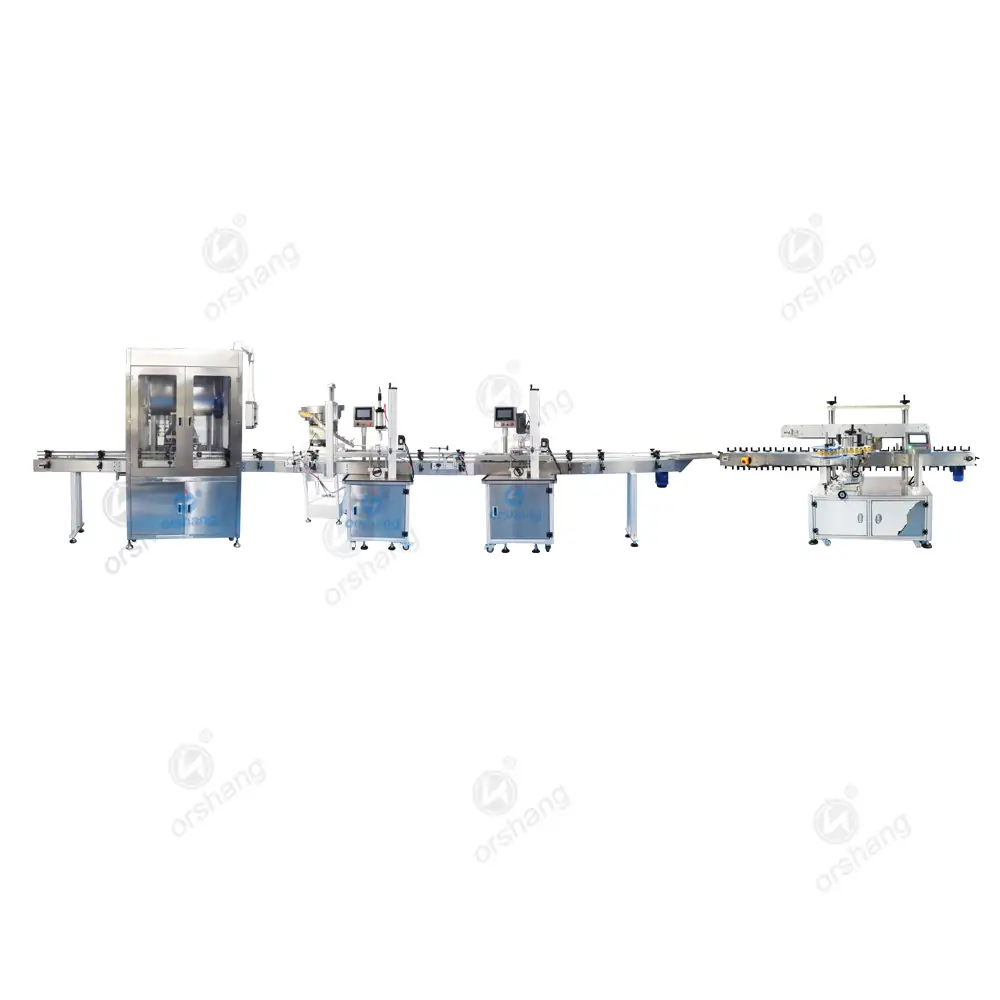

Mineral water filling line

Orshang mineral water filling line covers from mineral water bottles to water filling equipment, from water filling plant design to the delivery of automated production line, which gives you full support and service.

What is a mineral water filling line?

Mineral water filling line is engaged in the manufacturing of water bottling equipment and water packaging machines production line such as mineral water filling line, pure water filling line, mountain spring water filling and line etc. The advanced automation version of mineral water filling line includes raw water treatment system, filling system, packaging system and auxiliary equipment, while the small version includes: preform filling system and packaging system.

- Raw water treatment system: coagulation, sedimentation, specially designed filtration and disinfection processes and all other necessary processes aimed at preparing raw water for the production line.

- Filling system: the necessary equipment to achieve the target of filling mineral water, such as the filling machine, the bottle trimmer, the conveyor belt, etc. The equipment is used in packaging the treated water into the packaging containers.

- Packaging system: Such as capping machine for bottle, labeling machine, coding spraying machine, packaging machine for bottle etc. One of the functions is to seal, mark, code-spray, pack and other processing of the filled mineral water in order to achieve the versatility of the market filling requirements.

Product parameters:

| Labeling accuracy: | ±1mm |

|---|---|

| Labeling speed: | 20~40pcs/minutes |

| Applicable round bottle diameter: | Φ20mm~Φ310mm |

| Applicable length: | 0.2-150mm |

| Applicable width: | 40-200mm |

| Filling accuracy: | ±1mm |

| Filling speed: | 40~60pcs/minutes |

| Machine size (L*W*H) : | 7500*2000*1500(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 540KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Key benefits of a mineral water filling line

- High-efficiency automation: By adopting the new advanced automation control system, all activities from the movement of the empty bottle to the filling process, capping, screwing, sealing, labelling and output of the finished product are automated thus enhancing production productivity.

- High precision metering and quality assurance: With metering system of high precision, it can make sure that the amount of mineral water filled into every bottle is accurate enough to meet the high standard set by the customers on the quality of the products.

- Stable and reliable: the rigorous process involved in choosing a material and proper technology in manufacturing the equipment to avoid arbitrary breakdown, high maintenance costs and low productivity.

- Flexible customization: For individual customer requirements, there are of course blowing, shaping, bottle shape, filling volume, capacity, and later the bottle packaging machine to meet customer production needs.

- Cost-saving solutions:Automation cuts down on the cost of labour and leads to fewer mistakes ultimately, and provides value in the long-run.

Customisation filling plan:

We handle the entire filling planning, right from selection of equipment, design of production line to the improvement on processes of production line, feel free to consult us. Our professional engineers will design the best filing plan with reference to your production demands and site environment, which can maximize twice productivity and quality of the product.

Ideal markets:

The mineral water filling line enjoys its high popularity in various water filling factories such as the production of mineral water, pure water, spring water and various beverage production. No matter you are a small water factory ,or a large beverage enterprise, we can offer you the most appropriate water filling line.

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

Our mineral water filling line supports a wide range of bottle types, including but not limited to PET bottles, glass bottles, cans, plastic bottles and so on. Specific bottle types can be customised according to customers’ needs.

Our mineral water filling line is reasonably designed, simple in structure and easy to maintain and service. At the same time, we also provide comprehensive pre-sales consultation, after-sales service and lifelong technical support to ensure that your equipment is always in good running condition and free from worries.

The capacity of our mineral water filling line can be adjusted according to customer’s demand, ranging from a few hundred bottles to tens of thousands of bottles per hour. The specific capacity will be customised according to your production needs and site conditions.

Basically any market water filling is possible, as we can customise it according to your needs! Conventional 330ml, 500ml, 750ml, 15000ml, and some special 250ml, 375ml and so on!

Hi, our mineral water filling equipment is small, we have large and high speed bottled water equipment. You can expand the bottle washing machine, bottle blowing machine, sterilising machine, water packaging machine, mineral water cartoning machine, sealing machine.

Reviews

There are no reviews yet.