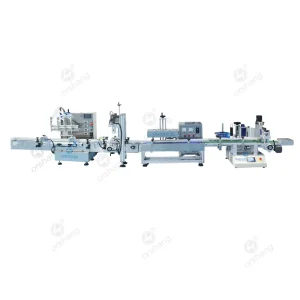

Линия розлива масла из горного перца и рапсового масла в бутылки

Современная линия розлива пищевого масла позволяет автоматизировать весь процесс — от подготовки бутылок до готовой упакованной продукции. Комплекс подходит для розлива рапсового масла, масла из горного перца, оливкового масла и других растительных масел, обеспечивая высокую точность дозирования, стерильность и стабильное качество продукции.

Как работать с видео-кейсом

Технические характеристики

| Labeling accuracy: | ±1mm |

|---|---|

| Labeling speed: | 20~35pcs/minutes |

| Applicable round bottle diameter: | Φ20mm~Φ100mm |

| Applicable length: | 20-310mm |

| Applicable width: | 15-150mm |

| Machine size (L*W*H) : | 16000*1100*2000(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 700KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Преимущества линии

Полная автоматизация — минимизация ручного труда

Асептический розлив — гарантированная безопасность пищевых продуктов

Универсальность — подходит для различных типов растительных масел

Экономия времени и затрат — высокая скорость и стабильность работы

Эстетичный вид продукции — качественная этикетировка и термоусадка

Применение

Линия розлива масла из горного перца

Линия розлива рапсового масла

Линия розлива подсолнечного масла

Линия розлива оливкового масла

Линия розлива ароматизированных масел

Линия розлива масла из горного перца

Линия розлива рапсового масла

Линия розлива подсолнечного масла

Линия розлива оливкового масла

Часто задаваемые вопросы

Да, наша линия розлива растительного масла подходит для рапсового, подсолнечного, оливкового, кукурузного, а также ароматизированных масел, включая острое масло из горного перца.

Да, оборудование совместимо с ПЭТ, стеклянными и другими пищевыми бутылками объемом от 250 мл до 2 литров.

Да, асептическая машина для розлива масла оснащена герметичной камерой с фильтрацией воздуха, предотвращающей попадание пыли и микроорганизмов.

Да, оборудование поставляется как комплекс, включая шейный этикетировщик, оберточную этикетировочную машину и термоусадочный модуль.

Производительность зависит от объема бутылок и типа масла, но в среднем составляет от 2000 до 8000 бутылок в час.

Призыв к действию

Хотите автоматизировать производство пищевого масла и увеличить выпуск продукции? Свяжитесь с нами и получите индивидуальное предложение на линию розлива масла в бутылки, адаптированную под ваши задачи.

Reviews

There are no reviews yet.