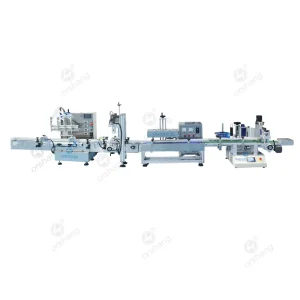

Perfumery rotary filling and capping machine

Welcome to Orshang perfume automated packaging production equipment page. We offer you an all-round automated rotary production line integrating perfume filling, screwing (capping) and labelling, designed to meet all your needs for perfume packaging production. With our line, you can achieve an efficient, precise and hygienic perfume production process that will make your products stand out in the market.

Product parameters:

| Filling precision: | ±1%-2% |

|---|---|

| Filling capacity: | 50ML |

| Filling speed: | 3000 bottles/hour |

| Applicable length: | 400mm |

| Applicable width: | 280mm |

| Applicable height: | 150 mm |

| Label sizes: | 300 mm |

| Machine size (L*W*H) : | 3400*3000*2100(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 1000KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Working principle:

Automatic Perfume Filling:

- The perfume production line adopts stepping motor for quantitative filling, and adjusts the filling volume and filling speed directly through the touch screen.

- In addition, it also adopts negative pressure filling technology to ensure that the liquid level of each perfume filling bottle is flush, and the excess material is recovered through the negative pressure tank. This design makes the whole filling process both efficient and precise.

Dual-station cap screwing/capping:

- The nozzle cap is automatically sorted out through the vibrating plate, and the robot automatically grabs the nozzle cap and completes the pre-taping function.

- The elastic cap rolling head ensures that the capped bottles are free from damage and have a beautiful appearance. This automation design greatly improves production efficiency and product quality.

Vibrating disc upper centre sleeve/pressure centre sleeve:

- The pressure centre sleeve is usually used to enhance the vibration effect of the vibrating disc. By adjusting the position and tightness of the press sleeve, the vibration characteristics and frequency of the vibrating plate can be changed, thus optimising the working performance of the vibrating plate.

Main features:

Automated Filling System:

- Efficient and accurate perfume filling, ensuring that the capacity of each bottle of perfume is accurate.

- Adopt advanced rotary filling technology to improve production efficiency.

Cap Screwing (Capping) System:

- Automated screwing (capping) process ensures that the caps are tight and leak-free.

- It can be flexibly adjusted according to the type of cap, adapting to a variety of perfume bottle types.

Labelling system:

- Precise labelling technology ensures flat labels and accurate position.

- Support a variety of label materials and sizes to meet your individual needs.

Whole line automation control:

- Adopting advanced PLC control system to achieve automatic control of the whole line.

- Real-time monitoring of production status, fault alarm timely response.

Ideal markets:

Our automated perfume production equipment is suitable for perfume packaging manufacturers of all sizes, small and medium-sized cosmetic producers, small handmade workshops or large-scale factories, all of which can find their own perfume solutions on this production line. With our production line, you can easily automate the whole process of perfume from filling to labelling, increase production efficiency and reduce production costs.

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

Yes, our production line can be flexibly adjusted to different sizes of perfume bottles to ensure that each bottle of perfume is handled with precision.

Our filling system adopts advanced rotary filling technology to ensure that the volume of each bottle of perfume is accurate and meets your stringent requirements on product quality.

Our production line adopts high-quality materials and advanced manufacturing technology to ensure long-term stable operation. Meanwhile, we provide perfect after-sales service and technical support to reduce your maintenance cost.

Our production line adopts advanced PLC control system to achieve automatic control of the whole line. You only need to set the parameters on the console, and the production line can automatically complete the whole process from filling to labelling.

Of course we can. With rich production experience and professional technical team, we can provide customised production line solutions according to your specific needs.

Reviews

There are no reviews yet.