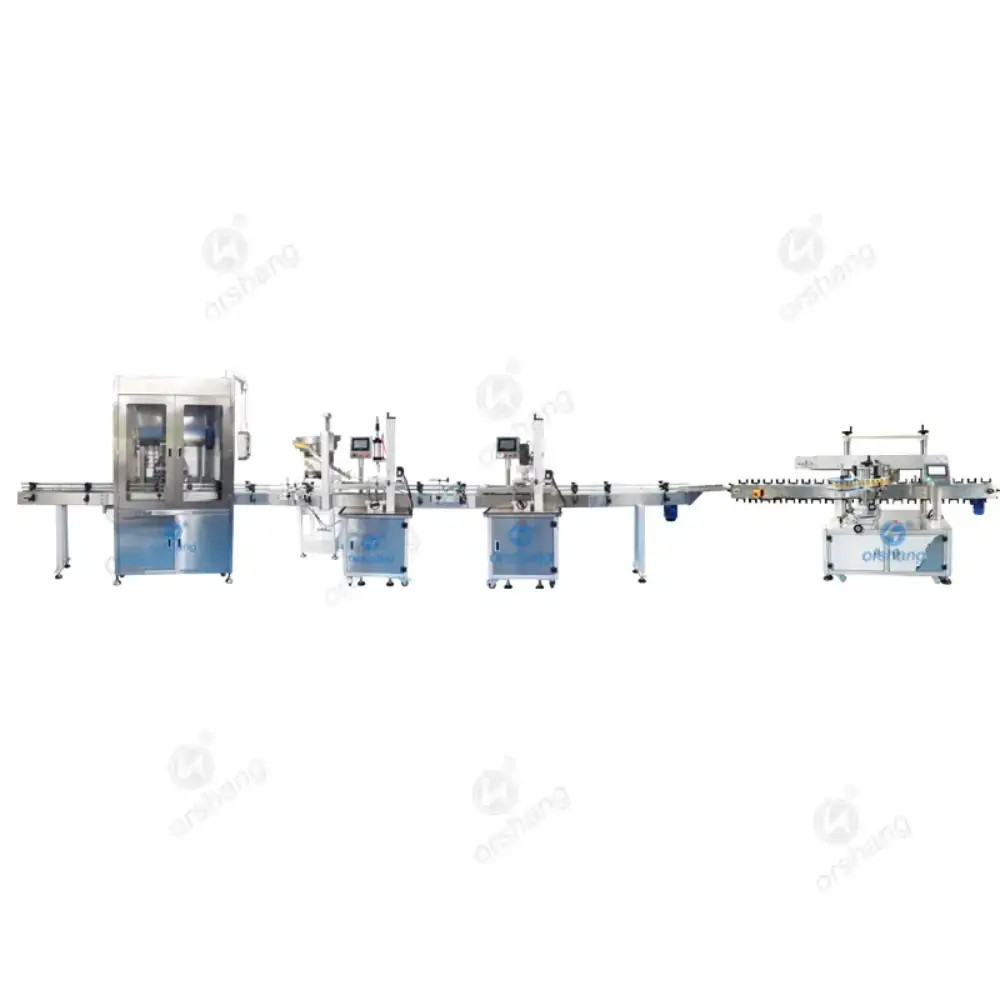

Автоматическое оборудование для розлива напитков и соков в бутылки

Надёжная и гибкая линия розлива безалкогольных и алкогольных напитков, разработанная для автоматической фасовки в бутылки, банки и другую потребительскую тару. Подходит для розлива воды, лимонада, соков, энергетиков, коктейлей, пива и кваса.

Оборудование объединяет: точный розлив, автоматическую укупорку (винтовую/прессовую), опциональную пастеризацию и маркировку, обеспечивая высокое качество упаковки и сохранность вкуса.

Посмотреть видео розлива соков и воды

Технические характеристики

| Точность наполнения: | ± 5 г |

|---|---|

| Скорость наполнения: | 30-50 бутылок в минуту |

| Скорость отвинчивания: | 30-40 бутылок в минуту |

| Точность нанесения этикеток: | ±1мм |

| Скорость нанесения этикеток: | 20-30 штук в минуту |

| Применимая ширина: | 25-400 мм |

| Применимая высота: | 0,2-200 мм |

| Применимая длина: | 20-300 мм |

| Размер машины (Д * Ш * В): | 7500*2000*1500 (мм) |

| Источник питания: | 110v 220v 230v 380v |

| Вес машины: | 540 кг |

| Минимальный объем заказа: | одна единица |

| Способ оплаты: | 50% предоплата и 50% после получения заказа |

| Информация об упаковке: | Все упаковано в деревянные ящики |

| Способ оплаты: | Аккредитивþ D/A þ D/ Pþ Western Unionþ Money Gram T/T Paypal |

Основные функции

Розлив – объёмный, поршневой или гравитационный (в зависимости от продукта)

Укупорка – автоматическая, под разные типы крышек: винтовая, кронен, пресс-крышка

Этикетирование – 1–3 зоны: корпус, крышка, шея

Автоочистка CIP – по запросу

Сенсорное управление – интуитивный интерфейс, хранение рецептов

Настройка под разную тару – от 200 мл до 2 литров, ПЭТ/стекло/банка

Принцип работы

Пустые бутылки подаются по ленте

Система выполняет точное дозирование напитка (по объёму, уровню или весу)

Бутылка автоматически укупоривается соответствующей крышкой

Наносится этикетка (в 1 или 3 зоны)

Продукт выходит на накопитель, готовый к упаковке

Преимущества

⚡ До 3000 бутылок в час

🔁 Быстрая перенастройка на разные напитки и тару

🧼 Соответствие санитарным нормам для пищевой промышленности

🧃 Подходит для негазированных и слабо газированных жидкостей

📦 Компактная конструкция для небольших производств

💰 Экономия на ручном труде и потере продукта

Подходит для:

Часто задаваемые вопросы

Да, в версии с изобарическим или противодавлением – идеально для CO₂-продуктов.

Да, доступны версии с пастеризатором и CIP-системой.

Машина легко перенастраивается под высоту, диаметр и тип горлышка.

От 1 до 2 человек: загрузка пустой тары + упаковка готовой.

Reviews

There are no reviews yet.