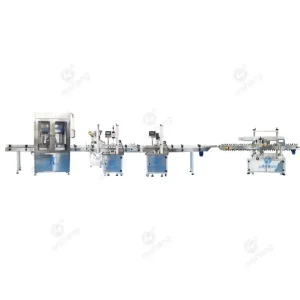

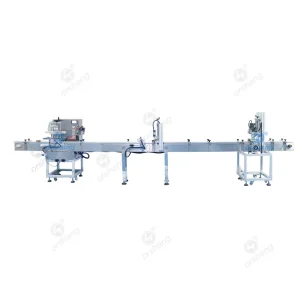

Оборудование для розлива минеральной воды в ПЭТ по бутылкам

Автоматическая установка для розлива минеральной воды в ПЭТ-бутылки разработана с учётом потребностей мелкосерийного производства и контрактных фасовщиков. Оборудование обеспечивает не только точный розлив и укупорку, но также включает функции:

ориентирования и подачи бутылок (сортировка/ориентация);

герметичного розлива в закрытом контуре (с защитой от пыли и бактерий);

автоматической подачи термоусадочной этикетки (шринк-рукав);

термоусадочной обработки для плотной фиксации рукавной этикетки;

автоматического нанесения самоклеящихся этикеток на корпус бутылки.

Посмотрите видео работы линии розлива воды

Технические характеристики

| Точность наполнения: | ±5-10 г |

|---|---|

| Скорость наполнения: | 40-60 бутылок в минуту |

| Скорость укупорки: | 20-30 штук в минуту |

| Точность нанесения этикеток: | ± 1 мм |

| Скорость нанесения этикеток: | 20-30 штук в минуту |

| Применимая ширина: | 25-400 мм |

| Применимая высота: | 0,2-200 мм |

| Размер машины (Д * Ш * В): | 16000*1100*2000 (мм) |

| Источник питания: | 110v 220v 230v 380v |

| Вес машины: | 700 кг |

| Минимальное количество заказа: | одна единица |

| Способ оплаты: | 50% предоплата и 50% после получения заказа |

| Информация об упаковке: | Все упаковано в деревянные ящики |

| Способ оплаты: | Аккредитивþ D/A þ D/ Pþ Western Unionþ Money Gram T/T Paypal |

Основные функции оборудования

- Ополаскивание пустых ПЭТ-бутылок

- Объемное дозирование минеральной воды

- Автоматическая подача и закручивание крышек

- Нанесение этикетки на корпус и/или горлышко бутылки

- Выход на накопительный стол или упаковку

Подходит для

Минеральная столовая вода

Лечебно-столовая вода

Негазированная питьевая вода

Слабо газированные напитки

Сайт по упаковке бутилированной воды

Часто задаваемые вопросы

Да, возможна модификация с системой давления и противопенного розлива.

Да, доступны форматы под любые ПЭТ-бутылки (от 200 мл до 2 л).

Reviews

There are no reviews yet.