Мини линия розлива водки и красного вина

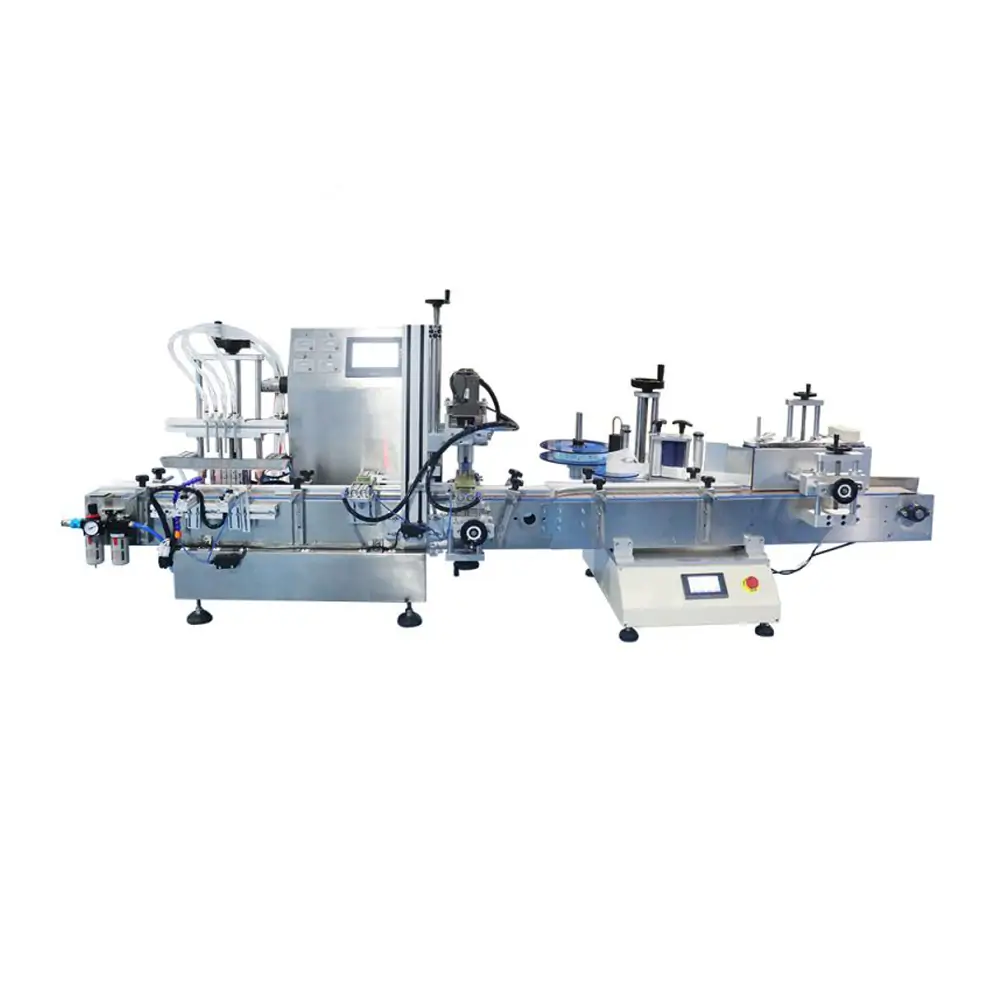

Компактная мини линия розлива водки и вина — это современное решение для небольших и крафтовых производств алкогольных напитков. Оборудование сочетает в себе розлив, укупорку и этикетировку в одном комплексе, что позволяет экономить пространство, время и затраты на персонал.

Подходит для бутылок объемом от 50 мл до 1 литра, обеспечивая высокое качество и точность дозирования.

Основные преимущества оборудования

Компактные размеры — легко устанавливается даже в ограниченном пространстве.

Высокая точность дозирования — исключает потери продукции.

Автоматизация процесса — от подачи бутылок до укупорки и этикетирования.

Гибкость настроек — для работы с различными объемами (от 50 мл до 1 л).

Соответствие стандартам качества и безопасности пищевой промышленности.

Видео о случае с линией розлива в бутылки

Технические характеристики

| Точность заполнения: | ±1% |

|---|---|

| Применяемый источник питания: | 110В 220 В 230 В 380 В |

| Максимальный расход: | 5 Л |

| Размер машины (Д * Ш * В): | 10000x1300x2100 (мм) |

| Мощность: | 4000 Вт |

| Минимальное количество заказа: | одна единица |

| Материал контактных частей: | нержавеющая сталь AISI 304/316 |

| Система укупорки: | винтовая крышка, корковая пробка, алюминиевая крышка |

| Тип напитков: | водка, красное вино, ликеры, настойки, игристое вино |

| Способ оплаты: | 50% предоплата и 50% после получения заказа |

| Производительность: | 20-35 шт/мин |

| Срок поставки: | около 15 рабочих дней |

| Информация об упаковке: | Все упаковано в деревянные ящики |

| Способ оплаты: | Аккредитивþ D/A þ D/ Pþ Western Unionþ Money Gram T/T Paypal |

Линия по розливу вина будет продана винодельням США в 2021 году:

Американская винодельня разливает по бутылкам не только вино, но и белое вино, желтое вино, шампанское и пиво!

Преимущества для вашего бизнеса

Экономия пространства — установка в небольших помещениях.

Снижение затрат на персонал — один оператор может обслуживать линию.

Гибкость — легкая перенастройка под разные напитки и бутылки.

Повышение качества продукции — точное дозирование и надежная укупорка.

Скорость выхода на рынок — быстрая установка и запуск в работу.

Применение

Мини завод по розливу водки

Линия розлива бутылок вина

Производственные цеха небольших виноделен

Крафтовые дистиллерии и винодельни

Производство сувенирной алкогольной продукции

Начинка из красного виноградного вина

Наполнение для виски

Соковая начинка

Правильный выбор минеральной воды, красного вина для производства винного напитка

для Вашей винодельни!

Оцените производственные потребности: Оцените свое текущее и планируемое производство, чтобы определить, подходит ли вам небольшая линия розлива или требуется большая линия розлива по бутылкам.

машина для розлива небольших бутылок

Машина для розлива и прикрепления этикеток в бутылки

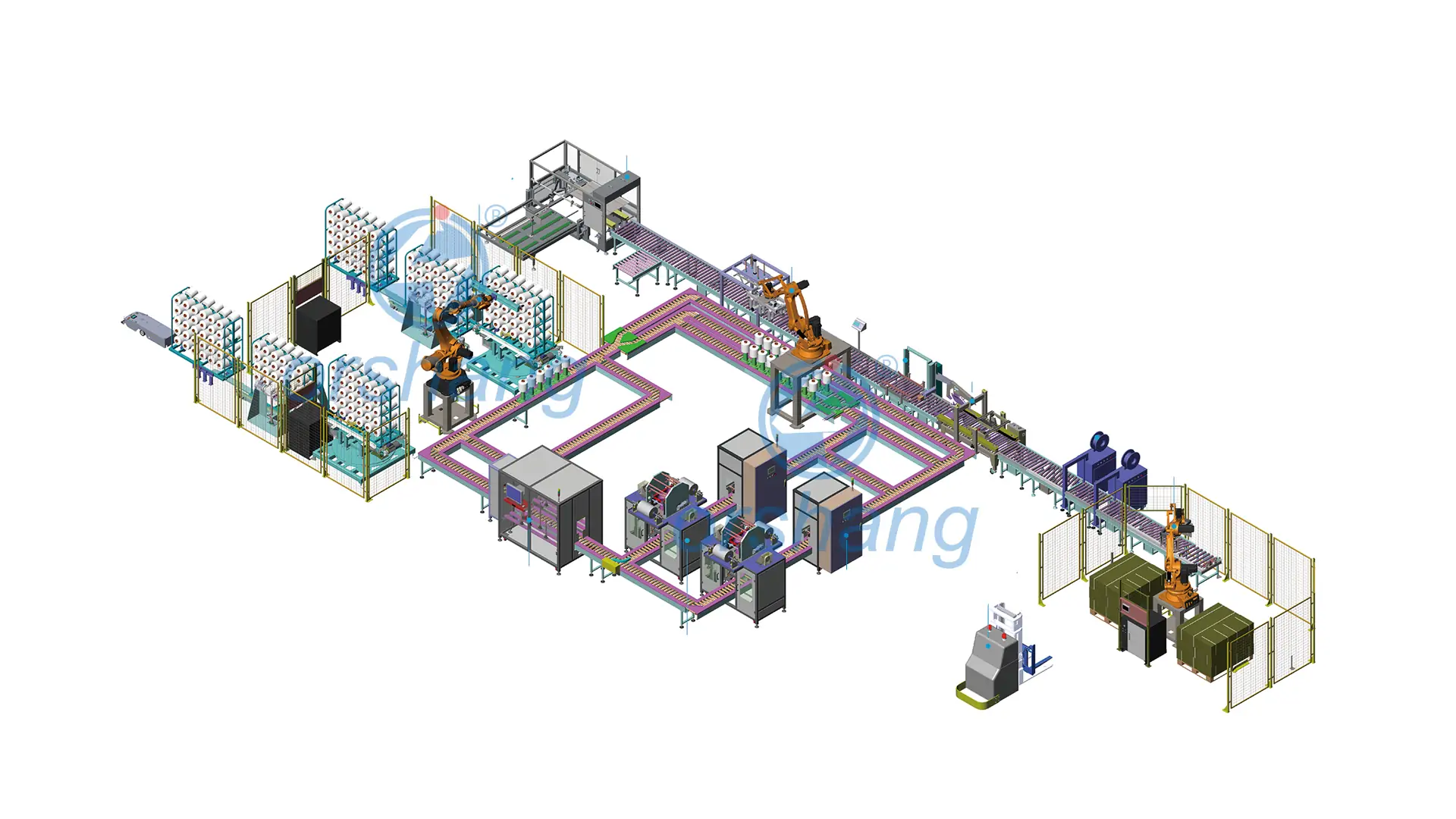

Заправочная линия с защитным кожухом

упаковочная машина для термоусадочных туннелей

Вывод: Инвестиции в современную линию розлива вина необходимы винодельням для повышения эффективности и поддержания качества продукции. И обеспечения масштабируемости с помощью линий по розливу ликеров, по розливу желтых вин, по розливу шампанского и по розливу пива. Выбрав линию, соответствующую вашим производственным потребностям, вы сможете обеспечить своему предприятию постоянный успех на конкурентном рынке.

Часто задаваемые вопросы

Да, наша мини производственная линия для алкоголя универсальна и подходит для водки, красного и белого вина, ликеров, коньяка и даже безалкогольных напитков.

Мини линии розлива позволяют работать с бутылками от 10 мл (например, мини-водка в сувенирной упаковке) до 1 литра.

Да, мини линия розлива вина идеально подходит для небольших виноделен и производителей авторских напитков, благодаря компактности и точной дозировке.

Конечно, мы предлагаем полный комплекс оборудования для розлива спиртных напитков — от розлива до укупорки и автоматического нанесения этикеток.

Обычно монтаж и запуск занимают от 1 часа, в зависимости от сложности и конфигурации оборудования.

Призыв к действию

Хотите быстро и качественно запустить производство водки или вина? Свяжитесь с нами, чтобы получить индивидуальное предложение на мини линию розлива, подходящую именно для вашего бизнеса.

Reviews

There are no reviews yet.