Линия розлива безалкогольных напитков и молока

Комплекс подходит для молока, йогурта, кефира, газированных и негазированных напитков, обеспечивая точность дозирования и высокую производительность.

Как работать с видео-кейсом

Описание продукта

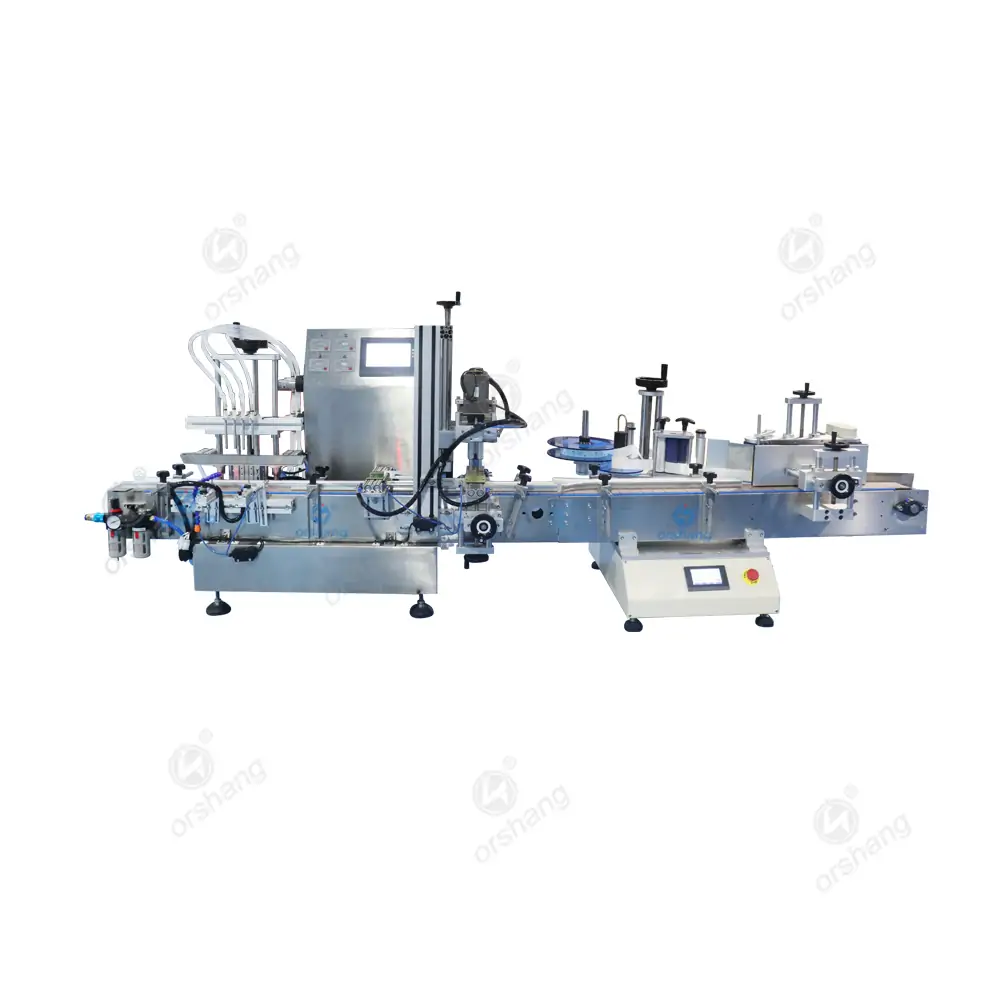

Данная автоматическая линия розлива молока и напитков в бутылки состоит из:

- Система подачи и ориентации бутылок — автоматическая загрузка тары.

- Асептический розливочный модуль — исключает контакт продукта с внешней средой, идеально подходит для молочных продуктов.

- Укупорочная машина — для пластиковых, алюминиевых и спортивных крышек.

- Этикетировщик — для самоклеящихся и термоусадочных этикеток.

- Автоматический кодировщик — для печати даты и партии.

- Приемный стол — аккуратный сбор готовых бутылок.

Технические характеристики

| Точность заполнения: | ±3% |

|---|---|

| Скорость нанесения этикеток: | 30-60 штук в минуту |

| Применимая длина: | 30-230 мм |

| Применимая ширина: | 30-60 мм |

| Размер машины (Д * Ш * В): | 2800*950*1100 (мм) |

| Источник питания: | 110 В 220 В 230 В 380 В |

| Вес машины: | 235 кг |

| Минимальное количество заказа: | одна единица |

| Типы бутылок: | ПЭТ, стекло |

| Материал: | нержавеющая сталь AISI 304/316 |

| Способ оплаты: | 50% предоплата и 50% после получения заказа |

| Производительность: | 20-35 шт/мин |

| Срок поставки: | ≧ 15 рабочих дней |

| Информация об упаковке: | Все упаковано в деревянные ящики |

| Способ оплаты: | Аккредитивþ D /A þ D / Pþ Western Unionþ Money Gram T / T Paypal |

Преимущества линии

Универсальность — розлив молока, кефира, йогурта, соков, газированных и негазированных напитков

Асептический розлив — продлевает срок хранения молочной продукции

Высокая автоматизация — снижение трудозатрат

Эстетичное оформление продукции — качественная этикетка и упаковка

Соответствие международным стандартам пищевой безопасности

Применение

Линия розлива молока в ПЭТ бутылки

Линия розлива йогурта и кефира

Линия розлива соков и молочных напитков

Линия розлива газированных напитков

Линия розлива спортивных безалкогольных напитков

линии розлива безалкогольных напитков

Машина для розлива, укупорки и запайки безалкогольных напитков

Часто задаваемые вопросы

Да, линия розлива молока и безалкогольных напитков универсальна и позволяет работать с молочными продуктами и газированными напитками при правильной настройке.

Да, автоматическая линия розлива молочных продуктов подходит для густых напитков и ферментированных молочных изделий.

В зависимости от модели и объема бутылок, производительность — от 3000 до 10 000 бутылок в час.

Да, стандартная комплектация включает термоусадочный туннель для групповой упаковки и защитных колпачков.

Закажите линию розлива молока и напитков уже сегодня

Если вы ищете автоматическую линию розлива молочных продуктов и безалкогольных напитков, мы готовы предложить оптимальное решение для вашего производства. Наши инженеры помогут подобрать оборудование с нужной производительностью, объемом бутылок и уровнем автоматизации.

Мы обеспечим поставку, монтаж, обучение персонала и сервисное обслуживание, чтобы ваша линия розлива молока в бутылки начала работать без сбоев с первого дня.

Reviews

There are no reviews yet.