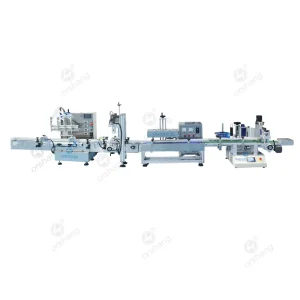

Продажа линии розлива газированных напитков и жидкого мыла

Благодаря модульной конструкции, линия розлива газировки может быть адаптирована под разную производительность — от 1000 до 6000 бутылок в час. Поддерживаются ПЭТ, стеклянные бутылки и пластиковые канистры.

Наглядное видео о том, как это работает

Описание продукта

Комплекс включает:

- Система подачи бутылок — автоматический ориентационный податчик.

- Моечная станция — для внутренней и внешней мойки тары.

- Асептический наполнитель — для напитков, предотвращает потерю газа.

- Дозатор для густых жидкостей — для жидкого мыла, шампуней, моющих средств.

- Укупорочная машина — винтовые, корковые или защёлкивающиеся крышки.

- Этикетировочный модуль — для самоклеящихся и термоусадочных этикеток.

- Маркировочное оборудование — дата, партия, штрихкод.

- Приёмный стол — сбор и упаковка готовой продукции.

Технические характеристики

| Точность заполнения: | ±10% |

|---|---|

| Скорость нанесения этикеток: | 25-35 шт /мин |

| Производительность наполнения: | 50-500 мм |

| Скорость укупорки: | 25-35 мм |

| Источник питания: | 110 В 220 В 230 В 380 В |

| Минимальное количество заказа: | одна единица |

| Типы бутылок: | ПЭТ, стекло |

| Материал: | нержавеющая сталь AISI 304/316 |

| Способ оплаты: | 50% предоплата и 50% после получения заказа |

| Производительность: | 20-35 шт/мин |

| Срок поставки: | ≧ 15 рабочих дней |

| Информация об упаковке: | Все упаковано в деревянные ящики |

| Способ оплаты: | Аккредитивþ D /A þ D / Pþ Western Unionþ Money Gram T / T Paypal |

Преимущества

Универсальность — подходит и для пищевых, и для непищевых жидкостей

Минимальная потеря CO₂ при розливе газировки

Лёгкая переналадка под разные типы крышек и бутылок

Соответствие санитарным и промышленным стандартам

Возможность интеграции с другими линиями

Применение

Линия розлива газированных напитков в ПЭТ и стекло

Линия фасовки жидкого мыла и бытовой химии

Оборудование для розлива энергетических напитков

Линия розлива шампуней и гелей для душа

Производственная линия по розливу газированной воды

Линия по упаковке и розливу жидкого мыла

Линия упаковки и розлива моющих средств

Часто задаваемые вопросы

Да, модульная конструкция позволяет быстро переключаться между продуктами.

Используется изобарическая технология розлива, сохраняющая CO₂.

Да, она совместима с шампунями, гелями, моющими средствами.

Да, мы можем продать один блок: разливочную машину, этикетировочную машину, машину для запечатывания алюминиевой фольгой

Закажите линию розлива уже сегодня

Если вам нужна линия розлива газированных напитков или оборудование для фасовки жидкого мыла, мы подберём оптимальное решение под ваши задачи.

Reviews

There are no reviews yet.