Линия розлива соков — купить оборудование для розлива фруктовых напитков жидкость

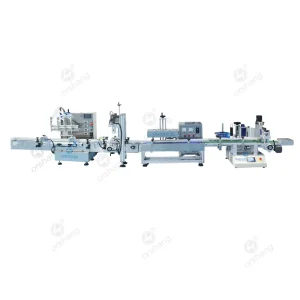

Автоматическая линия розлива соков — это комплексное решение для производителей,которым нужна стабильная производительность,Гибкость процесса асептического розлива и упаковки.

Линия поддерживает горячий розлив соков (85–92 °C), розлив нектаров и сокосодержащих напитков в ПЭТ и стеклянные бутылки с объёмом от 200 мл до 2 л. Конфигурация включает сортировочный блок, автоматический наполнитель, укупорочную машину,этикетировщик и приёмный стол, что обеспечивает непрерывный цикл от подачи тары до готовой продукции.

Как работать с видео-кейсом

Технические характеристики

| Совместимая тара: | ПЭТ、стекло |

|---|---|

| Габариты: | модульная компоновка под малую площадь установки |

| Точность нанесения этикеток: | ± 1 мм |

| Скорость нанесения этикеток: | 40 ~ 60 штук в минуту |

| Скорость наполнения: | ± 1-3% |

| Применимая длина: | 40-200 мм |

| Применимая высота: | 0,2-200 мм |

| Внутренний диаметр рулона этикеток: | Φ76 мм |

| Внешний диаметр этикетки: | φ280 мм |

| Размер машины (Д * Ш * В): | 8500 × 2000 × 2100 (мм) |

| Источник питания: | 110 В 220 В 230 В 380 В |

| Вес машины: | 850 кг |

| Минимальное количество заказа: | одна единица |

| Типы бутылок: | ПЭТ, стекло |

| Материал: | нержавеющая сталь AISI 304/316 |

| Способ оплаты: | 50% предоплата и 50% после получения заказа |

| Производительность: | 20-35 шт/мин |

| Срок поставки: | ≧ 15 рабочих дней |

| Информация об упаковке: | Все упаковано в деревянные ящики |

| Способ оплаты: | Аккредитивþ D /A þ D / Pþ Western Unionþ Money Gram T / T Paypal |

Описание продукта

Сортировочный и ориентационный блок бутылок

- Автоматически выравнивает и подаёт ПЭТ/стеклянные бутылки на транспортёр, снижая «узкие места» и исключая ручную подачу. Длинсортировщик бутылок для линии розлива соков。

Автоматическая машина розлива соков

- Режимы: горячий розлив для пастеризованных соков/нектаров; асептический для чувствительных напитков без консервантов。

Тип дозирования: гравитационный/массовый расходомер; опция клапанов под продукты с мякотью.

Контроль уровня и температурный контур для стабильной повторяемости.

Автоматическая укупорочная машина

- Совместима с винтовыми крышками(РР/HDPE)、спорт-колпачками、алюминиевыми крышками под стекло。укупорочная машина для соков в ПЭТ бутылки。

Автоматическая этикетировочная машина

- Поддержка самоклеящихся wrap-around, фронт/тыл, опция sleeve-термоусадка и шейный термоколпачок。этикетировочная машина для бутылок сока。

Автоматический принтер/датакодер

- Нанесение даты, партии, QR/штрихкода; интеграция в линию.

Приёмный стол / Автоматический сбор

- Аккуратная аккумуляция готовой продукции перед вторичной упаковкой; снижает простои и повышает OEE.

Преимущества

- Полный цикл «под ключ»:Разложите бутылку → наполните → закройте крышку → наклейте этикетку → закройте бутылку, первая строка сквозная.

- Горячий/асептический розлив:дольше срок годности.

- Высокая гибкость:Стакан PTt, 0,2–2 л, напиток с содержанием мякоти/низкой вязкостью.

- Стабильная производительность:точное доз.

Применение

Линия розлива соков в ПЭТ бутылки / стеклоPET

Оборудование для розлива нектаров и сокосодержащих напитков

Линия розлива холодного чая、витаминных

Розлив соков с мякотью

Горячий розлив пастеризованных продуктов

Розлив и укупорка сока в пакетики

Фасованная соковая начинка

Апельсиновая фруктовая начинка

Начинка-из-яблочного-сока

Часто задаваемые вопросы

Если продукт пастеризуется и допускает горячее розливание(85–92 °C),подойдёт линия горячего розлива соков。Для безконсервантных и «деликатных» рецептур рекомендуем асептическую линию розлива напитков с HEPA и изоляцией зоны.

Да. Ставим клапаны увеличенного прохода или поршневой/массовый дозатор,обеспечиваем равномерное прохождение взвеси без расслоения.

Да,линия розлива соков в ПЭТ бутылки и стеклянные бутылки поддерживает обе категории;смена формата выполняется через комплекты форматных частей.

Да,доступны к продаже сортировщик бутылок, автомат розлива соков, укупорочная машина, этикетировщик, приёмный стол — с последующей интеграцией.

Да,оборудование для розлива фруктовых напитков поддерживает нектары、напитки с сахаром/кислотностью,настройки CIP подбираем под рецептуру.

Да,по требованию добавим термоусадочный туннель、кейс-пакер、паллетизацию — формируем полный конец линии(EoL)。

Модульная компоновка позволяет вписать линию в компактную зону;уточним по планировке цеха и направлению потока сырья/тары.

Закажите линию розлива соков

Ищете, где купить оборудование линии розлива соков под ваш объём и рецептуры? Мы подберём конфигурацию сМеханизм отделки бутылок, автоматическое наполнение, автоматическое укупоривание, автоматическая маркировка, автоматический сбор бутылок с учётом тары, температуры розлива и требуемой производительности.

Reviews

There are no reviews yet.