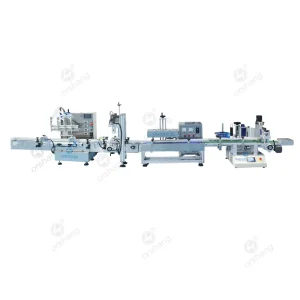

Автоматическая линия розлива напитка «Птичье гнездо»

Автоматическая линия розлива напитка «Птичье гнездо» включает следующие модули:

Автоматическая станция промывки бутылок

Удаляет пыль и загрязнения перед наливом.

Длинные хвосты: оборудование для промывки ПЭТ и стеклянных бутылок.

Одноголовочная разливочная машина

Точный дозированный налив напитков с кусочками желе, фруктов или мягкого геля.

Подходит для милк-дринков и десертных напитков.

Машина установки крышек

Автоматическая подача и размещение крышек на бутылки.

Машина закручивания и запайки крышек

Обеспечивает герметичность и сохранность продукта.

Возможна работа с алюминиевыми фольговыми вкладышами.

Этикетировочная машина

Нанесение самоклеящихся или термоусадочных этикеток.

Может печатать дату и номер партии.

Система сбора готовой продукции

Автоматический прием и группировка бутылок для упаковки.

Видео о том, как это работает

Технические характеристики

| Скорость розлива: | ±1% |

|---|---|

| Скорость мойки бутылок: | 20-30 бутылок в минуту |

| Скорость розлива: | 15-20 бутылок в минуту |

| Скорость укупорки: | 15-20 бутылок в минуту |

| Объем розлива: | 50 мл |

| Скорость кодирования: | 15-20 бутылок в минуту |

| Применимая ширина: | 6-250 мм |

| Размер машины (Д * Ш * В): | 10500*1500*2000 (мм) |

| Источник питания: | 110 В 220 В 230 В 380 В |

| Вес машины: | 450 кг |

| Минимальное количество заказа: | одна единица |

| Типы бутылок: | ПЭТ, стекло |

| Материал: | нержавеющая сталь AISI 304/316 |

| Способ оплаты: | 50% предоплата и 50% после получения заказа |

| Производительность: | 20-35 шт/мин |

| Срок поставки: | ≧ 15 рабочих дней |

| Информация об упаковке: | Все упаковано в деревянные ящики |

| Способ оплаты: | Аккредитивþ D /A þ D / Pþ Western Unionþ Money Gram T / T Paypal |

Преимущества

Полный цикл: от промывки до сбора готовых бутылок

Компактная установка — подходит для малых производств

Бережная работа с напитками с кусочками

Простая переналадка под разную тару

Высокий уровень гигиены благодаря автоматической мойке

Минимальные затраты на монтаж и обслуживание

Области применения

Розлив напитка «Птичье гнездо»

Розлив десертных милк-дринков

Розлив напитков с кусочками фруктов и желе

Небольшие партии функциональных напитков

- Вязкая медовая начинка

Упаковка и наполнение икры “Птичье гнездо”

Часто задаваемые вопросы

Да, одноголовочный дозатор адаптирован для вязких жидкостей и твердых включений.

Да, регулировка дозы выполняется в течение нескольких минут.

Нет, в составе линии есть автоматическая станция промывки бутылок.

Да, можно интегрировать дополнительный модуль по запросу.

Закажите линию розлива прямо сейчас

Оформите заказ на компактную автоматическую линию розлива напитка «Птичье гнездо» и получите готовое решение для полного цикла производства.

Отправьте заявку — мы подготовим предложение в течение 24 часов!

Reviews

There are no reviews yet.