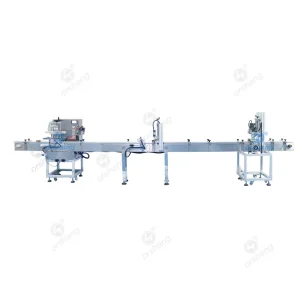

2 head desktop liquid paste filling machine

Equipped with two nozzles, our 2 head desktop liquid paste filling machine can also be expanded with 4-36 filling heads to handle different filling tasks, shortening the bottling time and improving the overall efficiency.

As a desktop semi-automatic liquid paste filling machine, it is ideal for small production lines with automatic bottle consolidation equipment, automatic filling equipment, automatic capping machine, and fully automatic labeling machine, integrating a variety of functions for easy operation and maintenance.

One machine is suitable for filling a wide range of materials such as liquids, pastes, creams, etc. and minimizes waste, making it ideal for companies that need to accurately fill a wide range of products from thin liquids to viscous pastes.

Product Parameters:

| Labeling precision: | ±1mm |

|---|---|

| Labeling speed: | 40~60pcs/minutes |

| Filling precision: | ±1-3% |

| Capping speed: | 20~30 bottles/minute |

| Applicable width: | 40-200MM |

| Applicable height: | 0.2-150MM |

| Machine size (L*W*H) : | 8500*2000*2100(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 850KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Working Principle:

The working principle of the 2 head desktop liquid paste filling machine is as follows:

Automatic Bottle Sorting Machine:

The integrated bottles go through the bottle sorting equipment so that the bottles are well arranged.

Conveyor Belt:

Through the conveyor belt, clean bottles get in the filling head position of the filling machine by the centering device to keep the relative position of the container mouth and the filling head reliable.

Start of filling:

The control system starts the filling program, the filling head is lowered to the tiny opening of the container and inserted, the dosing device and the control valves are opened to allow material to be filled into the empty container at the set flow rate and speed.

Filling Monitoring:

In filling process, flow rate of the material, the volume to be filled into each container and the position of the container is discovered in real sense enabling accurate control of the entire process.

At the end of filling:

when filling volume of set is full, the measuring device and control valve are closed, filler head is uplifted and removed from the container, by this time the container is ready for sealing and going to the next operation.

Vibrating plate:

During filling operation, the flow of bottle caps is orderly arranged by the vibrating plate before the bottles are conveyed on the vibrating plate to the capping machine.

Capping machine:

Sealed-in feature makes sure that every bottle is sealed tightly.

Labeling Machine:

Having an efficient labeling system in place it makes it easier to label each product appropriately to improve on its image.

Product Features Advantages:

The 2 head desktop liquid paste filling machine combines efficiency and precision with unique benefits including

Color touch screen control:

Adopt high-definition color touch screen interface, intuitively display the operating parameters and status, make the operation more convenient and humanized.

Multi-language support to meet the needs of different countries and regions.

Multi-need to choose:

Provide a variety of filling modes and parameter settings, which can be easily adjusted according to different material characteristics and packaging requirements.

Support the rapid switching of different specifications of containers, strong adaptability.

PLC control :

Equipped with advanced editable logic controller to ensure precise control and automatic operation in automatic filling filtration.

Realize highly automated operation, reduce manual intervention, improve production efficiency, one person can complete the whole filling line operation and monitoring.

Sanitary stainless steel material:

The whole machine is made of sanitary stainless steel, which is easy to clean and sterilize, and guarantees the hygiene and safety of the production environment.

Filling head can be adjusted individually:

Each filling head can be equipped with an independent height adjustment mechanism, which can be flexibly adjusted according to the container.

Expandable Devices:

[row_inner_3] [col_inner_3 span__sm=”12″]- 2, 4, 6, 8, 10, or 12 filling nozzles

- Longer nozzles (for bottom up filling to reduce foam)

- Skinny nozzles (for products that string or drip)

- Bottle sorting machines

- Labeling machines

- Bottle packaging machines

- Filling line

Ideal markets:

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

Our tabletop filling machines are suitable for liquids and creams such as sauces, shampoos, oils, creams and more.

In our proposed design of filling machine, it is easy is disassembling for cleaning and it requires little effort in general maintenance.

Ideally, companies should be able to oversee the operation of the machine with one to two individuals.

It is manufactured with state-of-art technology and has a one year warranty with technical support afterwards.

We provide comprehensive pre-sales, sales and after-sales service.

Equipment installation and commissioning, operation training, regular maintenance and fault repair, our professional team will provide you with timely and efficient technical knowledge and filling solutions!

Quick quote in order to solve the time

Reviews

There are no reviews yet.