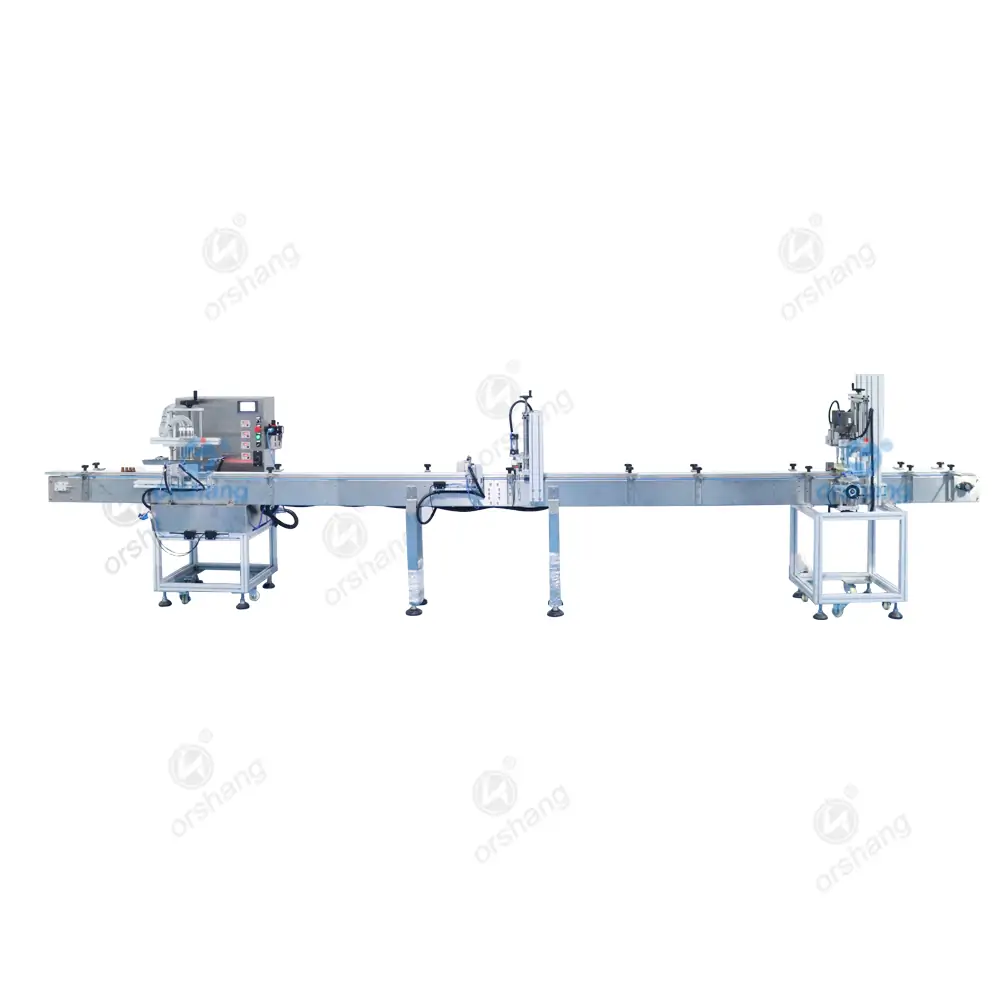

4 Heads Essential Oil Vial Filling Machine

Welcome to Ou Shang Automation Equipment Technology Co., Ltd, a manufacturer that has been specializing in automated packaging solutions.

From label deposition to label application, delicate bottle filling, or the precise screwing of caps, our equipment is perfectly adapted to your specific needs.

Whether you have PET bottles or conical bottles with irregular top and bottom, whether you produce large quantities of essential oils or pure solvents, our automatic vial filling machines ensure optimal management of the production chain.

Product Parameters:

| Filling precision: | ±5-10g |

|---|---|

| Pressure internal plug speed: | 2000~2500 pieces of bottles/hour |

| Filling speed: | 20~30 bottles/minute |

| Unscrewing speed: | 2000~2500 pieces of bottles/hour |

| Applicable width: | 25-100MM |

| Applicable height: | 25-300mm |

| Applicable length: | 20-200MM |

| Machine size (L*W*H) : | 5700*2000*2100(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 540KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Working Principle:

Placement of empty bottles to be filled:

Place the empty bottles of essential oils on the conveyor belt and transport them to the right underneath of the multi-head filling machine.

Filling material:

Under the action of vacuum suction, the essential oil is filled into the bottle by the 4-head tabletop filling, and as the liquid level of the essential oil in the bottle rises and reaches the set filling volume, the automatic filling machine stops working.

Filling is completed:

When the filling process is completed, the bottles filled with essential oils are transported under the automatic pressure corking equipment through the transportation belt.

Pressure inner stopper:

Cylinder pressure inner cork will automatically press the inner cork into the mouth of the essential oil bottle, and then go to the next process. (Adapt to different specification bottles)

Capping and screwing machine:

Automatically screws the caps onto the bottles with pressed inner corks, ensuring that each cap gets the proper tightening strength.

“This operation has been cyclic filling, High-speed essential oil bottler speed:20-30 bottles/minute The exact filling speed will also depend on your project needs”

Product Features Advantages:

4 Heads Essential Oil Vial Filling Machine’s unique advantages include:

Color touch screen control:

Adopting high-definition color touch screen interface, intuitively displaying various operating parameters and status, making the operation more convenient and humanized.

Multi-language support to meet the needs of different countries and regions.

Multi-need to choose:

Provide a variety of filling modes and parameter settings, which can be easily adjusted according to different material characteristics and packaging requirements.

Support the rapid switching of different specifications of containers, strong adaptability.

PLC control :

Equipped with advanced editable logic controller to ensure precise control and automatic operation in automatic filling filtration.

Realize highly automated operation, reduce manual intervention, improve production efficiency, one person can complete the whole filling line operation and monitoring.

Sanitary stainless steel material:

The whole machine is made of sanitary stainless steel, which is easy to clean and sterilize, and protects the hygiene and safety of the production environment.

Filling head can be adjusted individually:

Each filling head can be equipped with an independent height adjustment mechanism, which can be flexibly adjusted according to the container tell.

Vibrating plate:

During filling operation, the flow of bottle caps is orderly arranged by the vibrating plate before the bottles are conveyed on the vibrating plate to the capping machine.

Efficient:

The multi-head essential oil filling machine is equipped with four filling nozzles, which can fill four bottles together at the same time. It greatly improves the essential oil filling output, and our essential oil vial filling machine adopts advanced sensors and control system to ensure that each vial can be filled accurately and minimize product loss.

Low maintenance cost:

With a benchtop unit, user-friendly controller and easy-to-clean components, this high-speed essential oil filling machine is ideal for small producers and large production facilities alike.

Expandable Devices:

[row_inner_3] [col_inner_3 span__sm=”12″]- 2, 4, 6, 8, 10, or 12 filling nozzles

- Longer nozzles (for bottom up filling to reduce foam)

- Skinny nozzles (for products that string or drip)

- Bottle sorting machines

- Labeling machines

- Bottle packaging machines

- Filling line

Ideal markets:

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

Not complicated, essential oil bottling equipment operation is relatively intuitive, we have a professional technician before shipment of the equipment has been debugged, you get the equipment can be slightly installed can be used. Safety precautions and troubleshooting, etc.

The machine is manufactured with the most advanced technology, the warranty period is one year, and after the warranty period to provide lifelong technical support.

Essential oil four head benchtop filling machines are usually suitable for many sizes of essential oil bottles, whether they are PET bottles, small round 30ML bottles, glass or plastic bottles.

You can tell us your specific needs, usually our production line delivery cycle is about 15-30 working days. It also depends on your actual needs.

Of course you can, it is no problem to increase or decrease the number of filling heads, 2-36 heads can be installed.

Quick quote in order to solve the time

|

Reviews

There are no reviews yet.