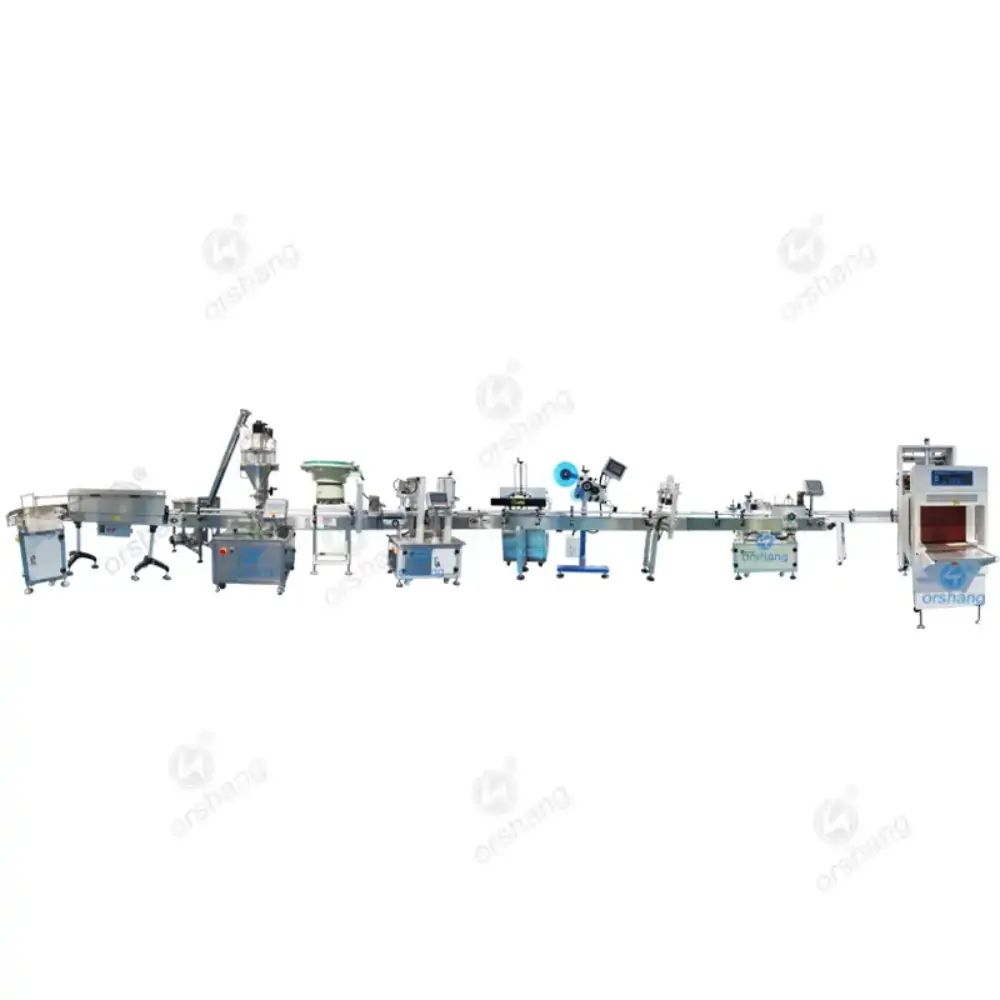

Твердый питательный порошок из молочного протеина для здоровья фасовочный аппарат для порошка

Данное оборудование предназначено для дозирования и упаковки твёрдых питательных порошков на основе молочного протеина включая изолят, казеин, сывороточный белок и другие спортивные и диетические добавки.

Система работает на основе шнекового дозатора с серводвигателем, что обеспечивает точную подачу даже плохо текучих и лёгких порошков. Установка соответствует стандартам GMP и пищевой безопасности

Описание продукта

Данное оборудование предназначено для дозирования и упаковки твёрдых питательных порошков на основе молочного протеина, включая изолят, казеин, сывороточный белок и другие спортивные и диетические добавки.

Система работает на основе шнекового дозатора с серводвигателем, что обеспечивает точную подачу даже плохо текучих и лёгких порошков. Установка соответствует стандартам GMP и пищевой безопасности

Видео-примеры фасовки по запросу

Основные функции

Шнековая подача с системой антислеживания

Высокоточная дозировка от 10 г до 2000 г

Фасовка в банки, саше, дой-паки или бутылки

Автоматическая запайка, отрез и укупорка

Гигиеничный разборной корпус из AISI 304/316

Возможность подключения весового контроля

Преимущества

Идеальна для протеиновых смесей, спортивного питания, сухого молока

Полная интеграция в линии с укупоркой и этикетировкой

Поддержка как автоматических, так и полуавтоматических решений

Поддержка микродоз: от 10 г для порционных форм

Модульная система: легко масштабируется под рост производства

Примеры фасуемой продукции

Сывороточный протеин

Сухое молоко и казеин Диетические добавки (BCAA, L-карнитин)

Функциональные смеси: клетчатка, витаминные комплексы

Ароматизированные белковые порошки

Где используется

Заводы по производству спортивного питания

Производители БАДов и диетических добавок

Контрактные фасовщики белковых смесей

Онлайн-бренды и private label продукты здоровья

Начинка из порошка специй,Начинка из порошка специй,Начинка из кофейного порошка

часто задаваемые вопросы

Да, предусмотрены системы пылеулавливания и виброочистки.

Да, поддерживается укупорка банок (автоматическая или полуавтоматическая).

Да, оборудование изготовлено из пищевой нержавеющей стали, герметичное исполнение.

Да, возможна адаптация шнека и использование двойного питателя.

Reviews

There are no reviews yet.