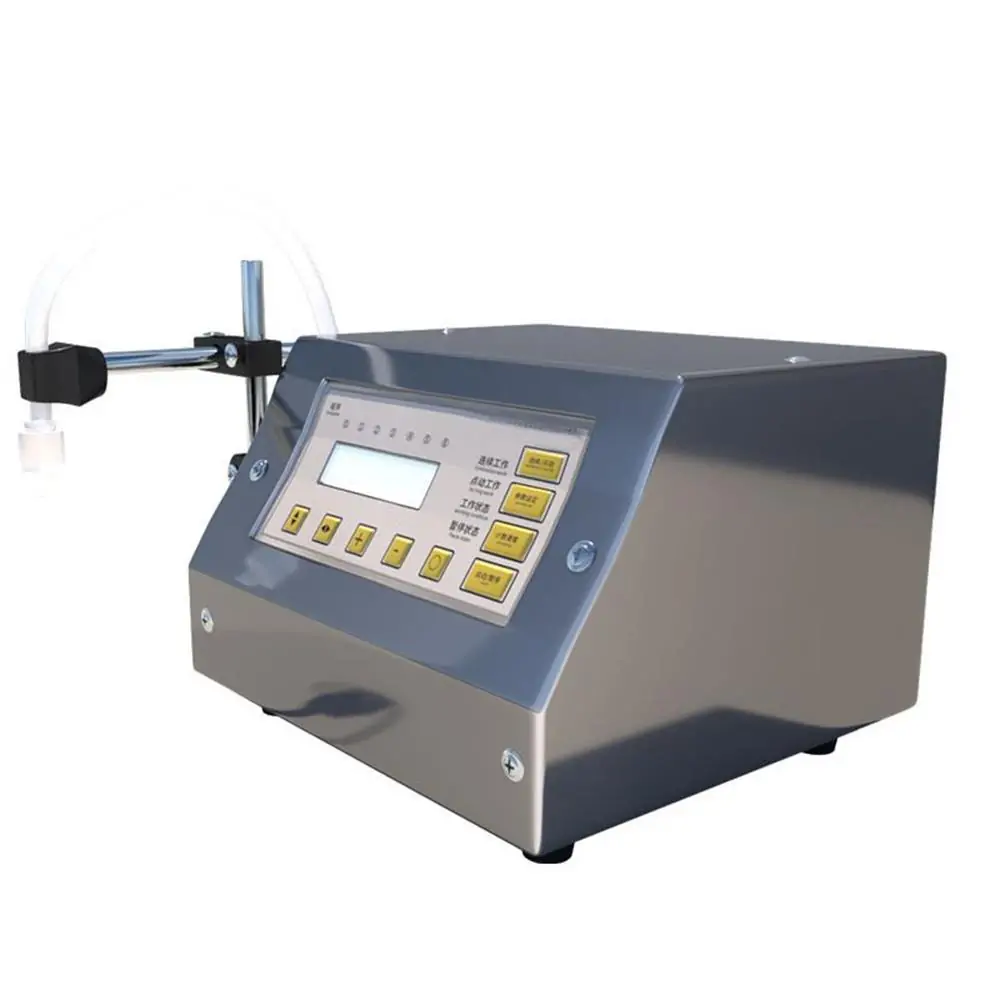

semi automatic tube filling machine product advantages:

One-key operation:

simple and clear operation interface, one-key start, bright colors, easy to achieve hose filling, no need for complex training, reduce labor costs.

CNC panel control:

intelligent control operation, liquid filling speed/time can be adjusted.

High-precision filling:

Equipped with high-precision filling head, it can accurately control the filling volume with an error of less than ±1% to ensure product quality.

Widely applicable:

the machine is suitable for various specifications of hose, whether small caliber or large caliber hose, can be easily dealt with.

Stainless steel body:

corrosion resistance, easy to clean, automatic heat dissipation protection of the body, use longer.

Reduce labor cost:

simple structure of the equipment, easy to disassemble and clean, easy maintenance, reduce labor operating costs.

Product parameters:

- Filling speed: 10-30 pcs/min (adjusted according to hose specification and filling volume).

- Filling volume range: 5ml-4500ml (can be customized according to customer needs).

- Power: 0.55KW.

- Voltage: 220V/50HZ (can be customized according to customer requirements).

- Appearance size:L280mm×W250mm×H160mm(can be customized according to customer’s requirement).

- Motor power:30W.

- Suction range:2M.

- Material leakage prevention: Yes (power failure memory function)

- Temperature: -10 ° to 80 °

Ideal markets:

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Reviews

There are no reviews yet.