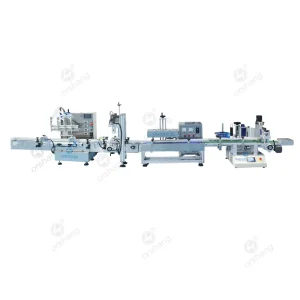

Bottle filling labelling capping machine

In modern manufacturing industry, bottle filling labelling and capping machine is an indispensable equipment which effectively integrates the process of filling, labelling and capping.

With this table-top small production line equipment, companies can achieve high efficiency packaging production and meet the growing market demand.

In this article, we’ll take a closer look at the features, benefits, and application areas of bottle filling, labelling, and capping equipment to help you make informed purchasing decisions.

Product parameters:

| Labeling accuracy: | ±1mm |

|---|---|

| Labeling speed: | 15~30pcs/minutes |

| Filling speed: | ±1-3% |

| Applicable length: | 0.2-150mm |

| Applicable width: | 40-200mm |

| Machine size (L*W*H) : | 4300*1100*1000(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 400KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Working principle:

One-touch start:

- the empty bottles are taken by the conveyor belt to the filling stay filling area.

The filling system starts: It fixed filling volume of the liquid or paste to be filled into the bottle.

The filling system starts:

- It fixed filling volume of the liquid or paste to be filled into the bottle.

Manual capping:

- The main operation is that after the bottle mouth is sealed by the sealing plate, the cap is opened by the opening lever and put on the bottle mouth manually by the operator. The bought by locations automatic capping machine can be expanded to such as.

Automatic cap screwing and capping machine:

- bottle comes into the cap screwing zone and the cap screwing machine screws the cap on the mouth of the bottle.

Labelling system:

- the labelled bottle moves into the labelling station where by the help of the preset parameters and position where the label was previously applied, it will be released and stick to the bottle or cap.

Main features:

- Efficient and accurate: The bottle filling labelling and capping machine also use sensors and positioning system, this can ensure accurate recognition of the position of the bottle mouth and the corresponding filling volume, the position of labelling and moderate force in capping to prevent products leakage or other quality problems due to improper operation.

- Flexible and multi-functional: it is an intelligent structure that can suitably accommodate different sizes and shapes of bottles and caps and high standard of filling, labelling and capping of products can be conveniently affected by simply changing the moulds or altering the setting.

- Stable and reliable: due to the high standards of calling all materials and high degree manufacturing technology, there is guaranteed steady operation of the machines, small failure rate and minimal maintenance demands.

- New users can also operate: reasonable man-machine cooperation, simple controls, convenient functions, that even non-experts can start the application.

Ideal markets:

Bird’s Nest Bottling Manufacturer: We provide one-stop packaging solutions for bird’s nest manufacturers, from product design to delivery.

Companies specializing in the production of paste food: automated packaging product needs for the food industry to meet diversified customization.

Manufacturer of health and wellness products: providing diversified packaging needs for paste and mucus filling.

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

Bottle filling, labelling and capping machine is a kind of automation equipment which integrates filling, labelling and capping together, and is widely used in the automated production of all kinds of liquid and paste products.

Bottle filling, labelling and capping machine is suitable for food and beverage, cosmetics, daily necessities, pesticides, pharmaceuticals and other industries, which can achieve accurate filling, labelling and capping of bottles of different specifications.

By adjusting the parameters of the filling system, such as pump speed, filling time, etc., you can achieve accurate control of the filling volume. The specific adjustment method can refer to the machine’s instruction manual.

By adjusting the parameters of the labelling system, such as the label conveying speed, the position of the label positioning sensor, etc., the precise control of the labelling position can be achieved. Meanwhile, the machine also has automatic correction and detection function to avoid label waste and leakage.

By adjusting the parameters of the capping system, such as the torque of the capping motor, the pressure of the capping wheel, etc., precise control of the capping strength can be achieved. Ensure that the caps are screwed to the proper degree to avoid product leakage or loose caps.

Reviews

There are no reviews yet.