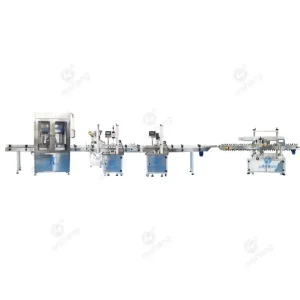

carbonated drink filling machine

Welcome to OrShang Automation Equipment Technology Co. We are experts in carbonated drink filling machine,in order to meet the food, carbonated beverages, soda, sparkling water, coffee energy drinks and other carbonated liquids, for the filling equipment is specially equipped with sealing door to reduce the contamination of the filling liquid also prevents the leakage of the logistics of the injury to employees.

Accurate and high-speed filling is achieved every time, the multifunctional carbonated beverage filling machine can handle a wide range of bottle sizes and materials and is ideal for a variety of production lines. Our equipment is easy to operate and maintain, helping to reduce downtime and increase overall efficiency.

Product Parameters:

| Labeling precision: | ±1mm |

|---|---|

| Labeling speed: | 40~60 pieces/min |

| Filling precision: | ±10g |

| Capping speed: | 20~30 bottles/minute |

| Applicable width: | 40-200MM |

| Applicable height: | 0.2-150MM |

| Applicable label size Length: | 20~310mm |

| Base paper width: | 15~150mm |

| Machine size (L*W*H) : | 6000*1200*2200(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 750KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Working Principle:

The carbonated drink filling machine works as follows:

Bottle feeding system:

containers plastic empty round bottles through the conveyor belt to convey the bottles to the filling equipment with airtight door.

Multi-head filling:

carbonated drink filling machine adopts four-head filling, according to the production demand, can also be customized to expand to 6 head eight head 12-36 head filling, can greatly improve the filling production efficiency, suitable for high-volume filling production.

Manual capping:

after the filling is completed, because of space constraints, there is no automatic capping equipment, and chose manual semi-automatic capping.

Capping equipment:

After the plastic round bottle is capped manually, the bottle enters the capping equipment, which automatically tightens the cap to ensure the sealing performance and prevent the beverage from leaking or losing air bubbles.

Automatic labeling machine:

bottles pass through the automatic labeling equipment, automatically affixed with self-adhesive labels to ensure that the information is clearly visible.

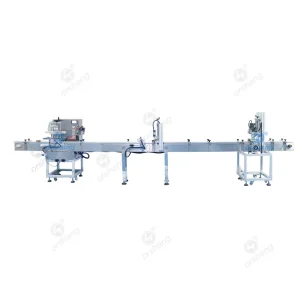

Bottle packaging machine:

bottle packaging machine equipment can be expanded to accurately package or transport.

Product Features Advantages:

Four head filling machine:

with four head filling design, carbonated drink filling into plastic bottles, suitable for small and medium-sized filling needs of enterprises.

Equipped with sealing door:

the filling equipment is equipped with openable sealing door design, when filling liquid or viscous materials, in order to prevent material leakage or external contamination, the four-head filling machine can close the sealing door, this design helps to keep the production of huaning clean and hygienic, especially suitable for food, beverage, cosmetic and other filling environment requires hygienic environment.

Manual capping:

n order to save space and cost, manual capping is chosen, which is suitable for small businesses with multiple product filling needs.

Labeling system:

automatic bottle labeling machine, no need for manual labor, automated self-adhesive bottle labeling can be completed.

Easy to clean and maintain:

simple design, easy to daily cleaning, reduce operating costs.

Ideal markets:

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

Of course you can, you tell us your demand, we will give you a perfect filling solution!

No matter it is beverage packaging and beverage filling can use this equipment, later production needs to increase can also be used with beverage bottling line!

When choosing a carbonated filling machine, consider the production capacity, the suitability of containers and bottles, the floor space and the budget and other related factors.

If you are still hesitant, you can discuss your project with us and we will give you the most reasonable automated filling and packaging solution.

We have already installed this equipment before shipment, we also have the relevant equipment drawings and installation video, or contact us, let us tell you.

We have stock and customized filling equipment.

If your product is suitable for our stock, we can ship it in about 7 working days, if you need to customize it, it needs to be shipped according to your needs 15-30 working days.

Reviews

There are no reviews yet.