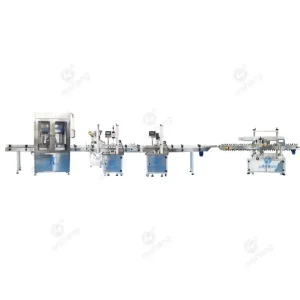

liquid detergent automatic filling and capping machine

Detergent filling machine is an indispensable automated and efficient equipment for modern detergent production line, our automatic liquid detergent soap filling machine ensures precise, fast and pollution-free automatic filling and capping machine. Thus, it realises the whole automatic management from raw material filling to finished product packaging.

One or two people can independently complete the liquid detergent detergent automatic filling capping machine.

Product Parameters:

| Filling precision: | ±5-10g |

|---|---|

| Filling speed: | 30~50 bottles/minute |

| Capping speed: | 20~30 pieces/minute |

| Labeling accuracy: | ±1mm |

| Labeling speed: | 20~30 pieces/minute |

| Applicable width: | 25-400MM |

| Applicable height: | 0.2-200mm |

| Applicable length: | 20-200MM |

| Machine size (L*W*H) : | 5700*2000*2100(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 650KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Working Principle:

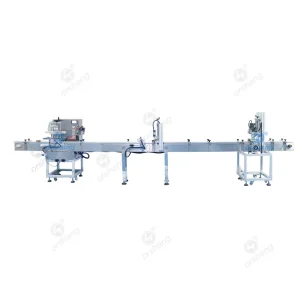

Conveyor Belt:

mpty bottles are automatically fed into the filling head position via a conveyor belt and the machine stops working temporarily.

Filling products:

This four-head tabletop filling machine is used, the number of canning heads is determined by the number of bottles to be filled, and also matched with the filling volume.

The liquid is filled into the bottle by the four-head bench-top filling machine, with four bottle page with the same is reached after the filling of the set amount, small bench-top filling machine temporarily stop working.

Single-head capping:

After finishing the canning, it enters into the next process through the conveyor belt, and the automatic single-head capping machine will screw the caps onto the bottles and seal them automatically.

Aluminium foil heat sealing machine:

when the bottle reaches the sealing machine, the equipment adopts the heat sealing technology to close the cap automatically, the sealing is firm and beautiful, suitable for all kinds of specifications of aluminium foil sealing needs.

Desktop round bottle labelling machine:

the last process of desktop automatic labelling machine, automatic identification of bottle type, accurate positioning of self-adhesive label position, rapid labelling. Easy to operate, reduce manual intervention, reduce the error rate

“In the whole vial filling production line, the artificial contact is minimised to achieve aseptic filling process, which also reduces manual intervention and improves production efficiency and product quality. ”

Product Features Advantages:

4 Heads Essential Oil Vial Filling Machine’s unique advantages include:

Color touch screen control:

Our exquisite vial filling and sealing equipment is designed with advanced technology to handle various sizes of vials and filling volumes to ensure precision and efficiency.

Automatic start-stop design:

Filling container conveying and filling operation are carried out at the same time, no container filling system stops working.

Easy to clean and maintain:

the whole machine is made of stainless steel, guaranteeing the hygiene and safety of the production environment.

Colour touch screen control:

adopting high-definition colour touch screen interface, intuitively displaying various operating parameters and status, making the operation more convenient and user-friendly.

Multi-language support to meet the use of different countries and regions.

Automatic start-stop design:

Filling container conveying and filling operation are carried out at the same time, no container filling system stops working.

Easy to clean and maintain: the whole machine is made of stainless steel to guarantee the hygiene and safety of the production environment.

PLC control:

Equipped with advanced editable logic controllers to ensure precise control and automated operation in automatic filling filtration.

Provide complete filling solution: integrated automatic filling, automatic capping and capping, automatic sealing, automatic labelling in one.

Expandable Devices:

[row_inner_3] [col_inner_3 span__sm=”12″]- 2, 4, 6, 8, 10, or 12 filling nozzles

- Longer nozzles (for bottom up filling to reduce foam)

- Skinny nozzles (for products that string or drip)

- Bottle sorting machines

- Labeling machines

- Bottle packaging machines

- Filling line

Ideal markets:

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

The machine is suitable for a wide range of pharmaceutical and cosmetic products such as liquids, powders and granules.

Of course, labelling and capping are expandable, not fixed. You can discuss your project with us and we will give you the perfect filling solution!

It is very easy to operate, it can be started by one button and the whole filling process can be done by one or two persons.

The specific price is not uniform, because the demand of vial filling is different, you can tell your demand, we will give you a quotation as soon as possible.

Yes, the machine can be adjusted according to the customer’s needs to adapt to different shapes and sizes of container bottles.

Reviews

There are no reviews yet.