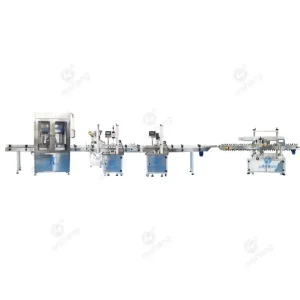

Машина для розлива, укупорки и этикетировки глазных капель и пероральных жидкостей

Orshang предлагает универсальную линию, сочетающую в себе розлив, укупорку и автоматическую наклейку этикеток на малые флаконы объемом от 5 до 30 мл.

Это решение идеально для производителей глазных капель, капель в нос, пероральных растворов, БАДов и жидкой косметики.

Видео с историей успеха:

Технические характеристики:

| Точность нанесения этикеток: | ±1mm |

|---|---|

| Скорость нанесения этикеток: | 40-60 штук в минуту |

| Точность наполнения: | ±10g |

| Скорость укупорки: | 20-30 бутылок в минуту |

| Применимая ширина: | 40-200MM |

| Applicable height: | 0.2-150MM |

| Применимая высота: | 0,2-150 мм |

| Ширина бумаги-основы: | 15~150mm |

| Размер машины (Д * Ш * В): | 5520*2000*2100(mm) |

| Материалы : | SUS304L (контактные детали) |

| Источник питания: | 110v 220v 380v |

| Вес машины: | 395 кг |

| Минимальное количество заказа: | одна единица |

| Тип укупорки: | Завинчивание / Прессовка / Алюминиевое обжатие |

| Способ оплаты: | 50% предоплата и 50% после получения заказа |

| Информация об упаковке: | Все упаковано в деревянные ящики |

| Способ оплаты: | Аккредитивþ D/A þ D/ Pþ Western Unionþ Money Gram T/T Paypal |

Как работает машина:

Подача флаконов на транспортер или вручную.

Автоматический розлив стерильной жидкости с перистальтическим насосом (без перекрестного загрязнения).

Подача и установка капельницы/пробки, затем автоматическая укупорка (винтовая или обжимная)

Этикетирование флакона с высокой точностью – круговая или передняя этикетка.

Сброс готовой продукции и автоматический контроль брака.

Преимущества:

3-в-1 решение: розлив + укупорка + этикетка в одном корпусе

Соответствует фармацевтическим стандартам GMP

Высокая точность дозировки и герметизация без утечки

Быстрая переналадка под разные форматыkar️

Компактность: экономит до 40% производственной площади

Возможность подключения к линии упаковки

Применение:

- Производство глазных и назальных капель

- Упаковка БАДов и растворов в каплях

- Лабораторные партии жидких лекарств

- Косметика: сыворотки, тоники в мини-флаконах

- Госпитали и частные фармзаводы

Наполнение чана белым вином

Бутылка “Птичье гнездо“

Фруктовый сок

Мед

Соевый соус

Минеральная вода

Часто задаваемые вопросы:

Да, машина настраивается под пипетки, капельницы, завинчивающиеся крышки, спреи.

Конечно. Машина универсальна для ПЭТ, ПП и стекла.

Перистальтический насос управляется сервоприводом, точность до ±0.5%.

Крышки: завинчивающиеся, нажимные (flip-top), с защитой от вскрытия (tamper-evident).

Укупорка: алюминиевые колпачки, термоусадочные пленки, индукционная запайка.

Тип этикеток: самоклеящиеся, термотрансферные или термочувствительные.

Система нанесения: автоматические аппликаторы с датчиками позиционирования.

Проверка: возможно оснащение камерой для контроля качества (правильность наклеивания, читаемость штрих-кода).

Зона розлива: может быть оснащена ламинарным потоком воздуха (класс чистоты A/B).

- Дезинфекция: опции CIP (Clean-in-Place) или SIP (Sterilize-in-Place).

Компактные версии: 500–2000 флаконов/час.

Промышленные линии: до 10 000 флаконов/час.

Да, возможна интеграция:

Принтеров для даты/партии.

Лазерной гравировки.

Систем RFID/NFC для отслеживания.

Reviews

There are no reviews yet.