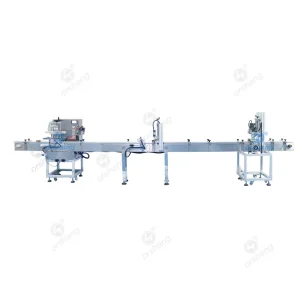

Product Parameters:

| Filling accuracy: | ±1%-2% |

|---|---|

| Filling capacity: | 50ML |

| Filling speed: | 3000 bottles/hour |

| Applicable width: | 280MM |

| Applicable height: | 150MM |

| product length: | 400MM |

| Overall size (L*W*H): | 3400mm*3000mm*2100mm |

| Overall weight: | 1000KG |

| Delivery time: | 7 days(Spot) 15-30days(customizable) |

| Minimum order quantity: | one unit |

| Port of shipment: | Shenzhen and Guangzhou |

| Payment: | 50% deposit, 50% after acceptance (full payment for shipment) |

| Delivery capacity: | 20-35 pcs/min |

| Delivery time: | 15-30 days |

| Packing Information: | All packed in wooden case |

| Payment method: | L/C þ D/A þ D/P þ Western Union þ Money Gram ¨ T/T¨ Paypal |

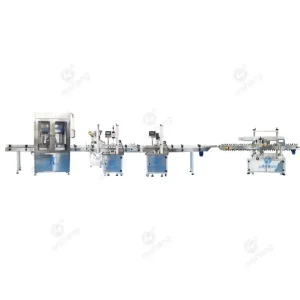

Working Principle:

1. Negative pressure filling technology:

This perfume filling production equipment adopts negative pressure suction filling technology, through the formation of a vacuum environment,so that the liquid is accurately sucked into the variety, to ensure that the filling liquid level is flush, and the excess material is recovered through the negative pressure tank. This way helps to ensure the accuracy and stability of the filling.

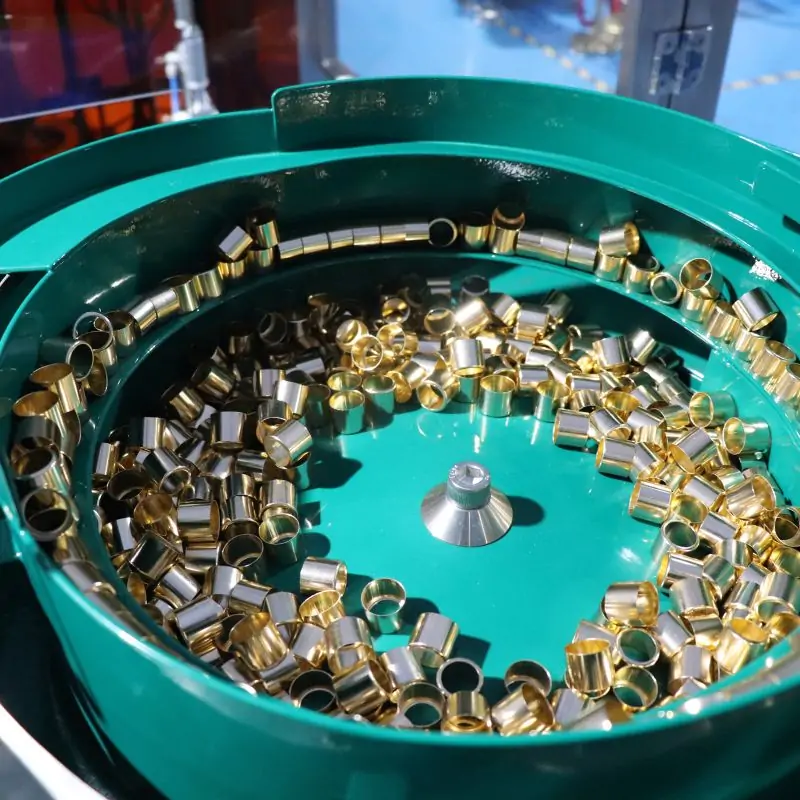

2. Dual position screwing/capping:

The nozzle cap is automatically organized through the vibrating plate, and the robot automatically grabs the nozzle cap to complete the pre-capping function. The elastic rolled cap head ensures that the bottle after rolled cap has no breakage and beautiful appearance. This automation design greatly improves production efficiency and product quality.

3. Center sleeve/press-in sleeve on vibration plate:

Press-in sleeves are often used to enhance the vibration effect of the vibrating plate. By adjusting the position and tightness of the press-in sleeve, the vibration characteristics and frequency of the shaker can be changed to optimize the working performance of the shaker.

Product Features Advantages:

1. Simple operation:

2. One machine multi-purpose:

3. Easy to clean and maintain:

4. Small footprint:

5. Easy Integration:

Ideal markets:

Perfume rotary filling machine

Mineral water filling

Perfume filling

Hand sanitizer filling

Oil filling

beer filling

Case Video:

FAQ:

As a filling market leader, we have earned a reputation for delivering the best in quality and reliability.

Our dedicated engineers and support staff are committed to helping our customers around the world with global automated packaging machine solutions. Our superior technical capabilities and global network enable us to provide targeted solutions to meet the diverse needs of our customers.

Yes, we can customize it, you can discuss your project with me, tell us more information, we give you customized automatic rotary filling machine solution that suits you better.

Small footprint, efficient filling, less waste, and the ability to fit different types of bottles.

1. Before ordering, we will adjust the relevant parameters according to your bottle filling requirements, you get the machine can be used.

2. Later to adjust the filling demand and speed, we will train you how to operate in advance.

Reviews

There are no reviews yet.