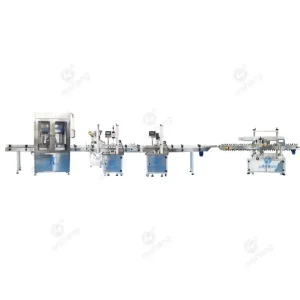

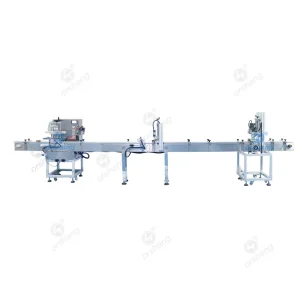

lubricating Oil Bottle Filling Equipment

Your preferred supplier of lubricant filling machines uses state-of-the-art filling technology to accurately and efficiently fill automotive motor oils and lubricants into a variety of different bottles.

This covers the entire process of lubricant filling equipment, automatic bottle capping machines and automatic bottle labelling machines. We also offer customised non-standard filling machines. To meet the needs of small scale operations and large scale businesses.

Product Parameters:

| Filling precision: | ±1% |

|---|---|

| Labeling accuracy: | ±1% |

| Filling speed: | 30~40 bottles/minute |

| Labeling speed: | 40~60 bottles/minute |

| Capping speed: | 20-40pcs/minutes |

| Applicable width: | 280MM |

| Applicable height: | 150mm |

| Applicable length: | 400MM |

| Machine size (L*W*H) : | 7900*1270*1140(mm) |

| Power supply : | 220V/50HZ |

| Machine weight: | 660KG |

| Minimum order quantity: | one unit |

| Shipping Port : | Guangzhou/shenzhen |

| Payment Method: | 50% deposit and 50% after acceptance |

| Delivery Capacity : | 20-35pcs/min |

| Delivery Time: | ≧15 working days |

| Packing Information: | All packed in wooden crates |

| Payment Method: | L/Cþ D/A þ D/Pþ Western Unionþ Money Gram T/T Paypal |

Working Principle:

Lubricant flat bottle filling:

The equipment accurately conveys the empty bottles to the filling area by means of a high-precision conveyor system.

The filling pump accurately injects the lubricant into the flat bottle container through the preset filling volume.

During the automatic filling process, the equipment adopts advanced control system to ensure the accuracy and consistency of each filling.

Vibrating disc cap screwing:

The bottle caps are neatly arranged by vibration and transported one by one to the designated position for subsequent capping operation.

The vibrating disc automatically distributes the caps to each bottle opening by vibration action.

The capping machine will then screw the caps accurately onto the filled bottles along with the arranged caps.

Automatic Aluminium Foil Sealer:

After the bottles have been screwed on, the bottles enter the aluminium foil heat sealing area.

The automatic sealing machine closely combines the aluminium foil with the mouth of the bottle through heat sealing or ultrasonic wave, etc., to achieve the purpose of sealing and prolonging the shelf life.

Desktop vertical positioning bottle labelling machine:

After the sealing of automobile motor oil bottle is completed, the bottle enters into the labelling area, and the self-adhesive printed label is accurately affixed to the designated bottle body position of the round bottle.

Desktop plane bottle cap labelling machine:

After the bottle is labelled and goes into the next process, the anti-counterfeiting label will be affixed on the bottle cap, which is convenient for product anti-counterfeiting and tracking.

Product Features Advantages:

Highly automated and integrated:

The lubricating oil filling equipment realizes a fully automated production process, from filling to sealing and labelling, reducing manual intervention and labour intensity.

High filling precision:

Using advanced metering pumps and control algorithms, both lubricant bottle filling machines and motor oil filling machines ensure that the same preset amount of lubricant is filled each time with minimal error.

Adaptable:

These devices can be adjusted and optimised for different sizes and materials of bottles as well as different types of lubricants, to meet the needs of a variety of production scenarios, such as different lubricants automotive engine oil filling, engine oil filling machine and lubricant packaging machine

Simple operation:

The use of advanced PLC control system and touch screen operator interface, making lubricant bottling equipment, engine oil filling machine and other equipment more simple and convenient, while the equipment also has a fault self-diagnosis function, easy to maintain and manage.

Stable and reliable:

The equipment adopts high-quality materials and advanced manufacturing process to ensure the stability and reliability of the equipment.

Expandable Devices:

[row_inner_3] [col_inner_3 span__sm=”12″]- 2, 4, 6, 8, 10, or 12 filling nozzles

- Longer nozzles (for bottom up filling to reduce foam)

- Skinny nozzles (for products that string or drip)

- Bottle sorting machines

- Labeling machines

- Bottle packaging machines

- Filling line

Ideal markets:

White wine vat filling

Bird’s nest bottle

Fruit juice

Honey

Soy sauce

Mineral water

Case Video:

FAQ:

Because each customer’s needs are different, there is no uniform price. Some of our customers’ needs are customised lubricant oil filling equipment, some of our stock filling machines can also meet the lubricant oil filling needs. You can discuss your project with us. We give the most perfect programme!

Yes, of course! Lubricant filling machine we have height self-adjustable filling head and flexible conveyor system, can easily adapt to various shapes of bottle filling, no matter your bottle is big or small, round or square, we can fill it accurately and meet your diversified needs.

Designed with easy disassembly and cleaning in mind, maintenance is convenient and can reduce downtime.

Our equipment is designed with environmental considerations in mind, using low carbon technology and materials to ensure that the equipment has a very small carbon footprint in the filling filtration. Compared to semi-automatic filling equipment, our products can significantly reduce the carbon footprint, adding a green and sustainable force to your life.

The production capacity can vary depending on the model and product characteristics, usually between 30 and 120 bottles per minute.

Quick quote in order to solve the time

|

Reviews

There are no reviews yet.